Girard-Perregaux Constant-Force Escapement

Since the days of Galileo and his perpetual motion design, the world has dreamed of overcoming friction with endless kinetic energy. Physicists agree that perpetual motion is a myth, but you can dispel all mythological notions by seeing a watch with a Constant Escapement at Baselworld 2013.

A few years ago Girard-Perregaux announced a constant-force escapement based on a revolutionary concept founded on the elastic properties of a silicium buckled-blade.This component, thinner than a human hair, delivers constant impulses of energy to the oscillator and prevents diminishing torque provided by the barrel’s mainspring from altering the accuracy of the movement.

Just a few watch companies have found ways to achieve constant force using a so-called remontoire d’égalitée, but Girard-Perregaux provides a constant force escapement without a remontoire. We know of only one other watch with a constant force device, not being a remontoire d’égalitée and that is the Tensus by Heritage Watch Manufactory, a watch that we absolutely love here at Monochrome.

However, a few years after the initial launch of the idea, Mike Margolis, Girard-Perregaux U.S. President, told me, “Oh you will see our Constant Escapement in a watch at Basel!” Which watch you ask? Well, mum is the word. Incidentally, the name of the escapement refers to one of GP’s founders, Constant Girard, but the double entendre is intentional.

What is an escapement?

An escapement is the heartbeat of the watch and responsible for the ticking that you hear when holding the watch next to your ear. If you have a see-through caseback, you can see the balance wheel of a watch’s escapement oscillating.

The escapement parcels out the power from the barrel’s mainspring in precise increments, allowing the hands to move.

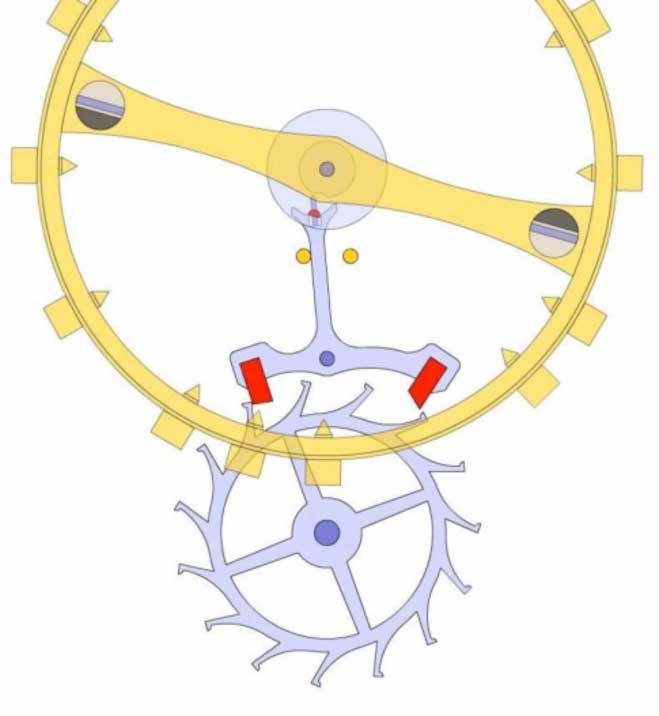

In a typical lever escapement (see image left), the energy of the mainspring comes through the gears to the escape wheel, pictured in blue.

All the power would immediately drain from the watch if not for the lever, also pictured in blue, with its pallets (pictured red).

The escape wheel provides impulse to the lever, which transfers that energy to the balance wheel (pictured gold).

The balance wheel spins to its limit, then returns to move the lever; spins the other direction, and returns to move the lever again.

Every time the balance wheel is in its center position, the lever moves allowing the escape wheel to move one click, which also propels the balance wheel in the other direction. At the end of a click, the pallets on the lever arrest the escape wheel until the balance wheel recoils. This common escapement style is a Swiss lever escapement.

There are two problems with a traditional Swiss lever escapement.

1. Decreasing amplitude when the power from the main spring decreases

2. Friction

1. For a mechanical watch, amplitude is the magnitude of change between the balance wheels oscillations. Every mechanical watch is adjusted to 5 or 6 isochronisms, for only one reason, and that reason is to let the watch run as precise as possible. After the watch is adjusted, it has a certain amplitude, and that amplitude changes during the course of unwinding the mainspring. When that happens, the chronometric rate drops, hence the watch no longer runs as precise as it should. The Constant Escapement provides consistent power, meaning a constant amplitude, and constant amplitude equals constant force – problem solved.

2. The other problem is friction. Typically, the lever touches the escape wheel, and its pallets slide against and meet the escape wheel’s teeth. In addition, friction is a problem with the lever contacting the balance wheel. The contact of these working parts requires oil and routine maintenance. Friction decreases accuracy, and the Constant-Force Escapement minimizes friction almost to the point of non-existence. The Constant-Force Escapement defies friction with the key ingredient of silicon for the buckled-blade. It also uses two escape wheels instead of one and a lever that contacts them with ultra-precise indexing, meaning there is increased technological precision in how the lever contacts the wheels. Friction becomes miniscule – another problem solved.

To understand this victory over decreasing power and friction, we need to understand how the Constant Escapement works.

The story begins with Nicolas Déhon who invented the movement while bending his train ticket. Boredom is the mother of invention. As Nicolas bent and released the ticket, he recognized the stored energy of the bent ticket that dissipated when the ticket unbent and then accumulated when it bent again. What he observed were the variations of stable and elastic properties, which GP employs in its thinner-than-a-human hair, silicon buckled-blade.

The buckled-blade is how Gerard-Perregaux achieves constant force. It fits between two fixed positions of the spring-frame, looking like a thin line at rest, and will buckle wave-like on either side of the impulse levers to release an infinitesimal millijoule with each oscillation. With such a small release, the power reserve is tremendous, and smaller amplitudes of shorter duration occur.

What comparison does justice to such a small amount of energy, a feather’s touch, a baby’s breath?

Nicolas had the idea, but it would take years before the material silicon could make it a reality. In 1999, Rolex first created a pre-silicon prototype of Dehon’s idea, but abandoned the project, leaving it to Girard Perregaux to realize in 2008. What Rolex lacked in silicon then, Gerard-Perregaux has in spades now. The silicon oxide of the buckled-blade is what allows continuous impulses to the balance wheel. The silicon’s contradictory properties of hardness and flexibility allow the blade to move from a stable state (stationary) to a metastable state (buckled), releasing energy until the mainspring depletes.

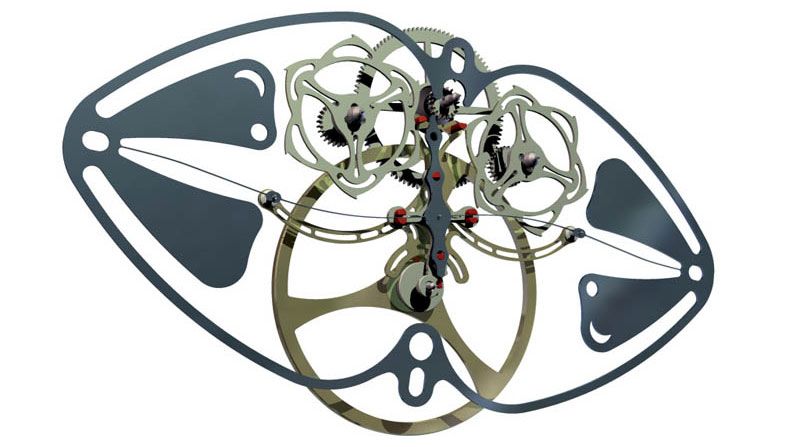

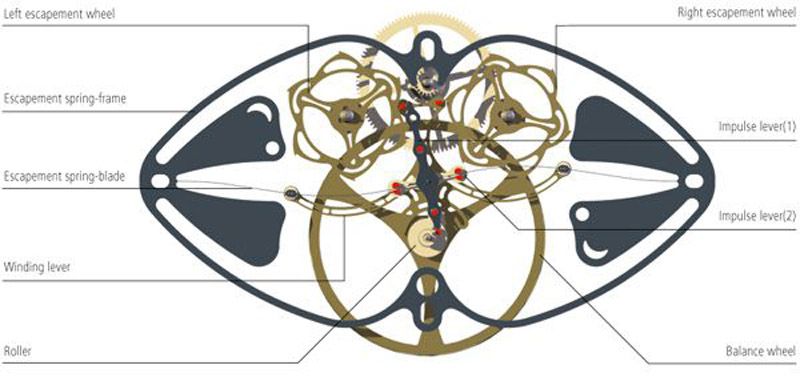

At first blush, the Constant Escapement may look like a traditional lever escapement complete with a balance wheel and balance spring, but notice the two escape wheels and two levers, plus the all-important buckled-blade. The left escapement wheel provides energy to the winding lever, which causes the blade to deform, providing a gradual accumulation of energy into the blade, which acts as an energy micro-storage unit to the point where the blade would flip to its opposite stable state. The small lug on the escape wheel tooth locks the blade and positions perfectly the fork of the impulse lever.

At the midpoint of the balance wheel’s cycle, its roller will make contact with the impulse lever fork and unlock the blade, which in return will flip to its opposite position. Doing so, it gives an impulse to the balance wheel and moves the winding lever the other direction. The other escape wheel will then bend the blade again. In traditional fashion, the balance wheel moves the winding lever between the two escape wheels much like a Swiss lever moves between the teeth of a single escape wheel. Far from traditional, the buckled-blade supplies this power. The impulse the blade gives is constant as it always releases the same energy when flipping. The given impulse remains unaffected as the mainspring winds down, providing the balance wheel constant amplitude. The escapement may look lever-like, but all similarities end with the buckled-blade.

A video might help:

The visual aspect of the Constant Escapement is striking. The architecture for the Constant Escapement is a paradigm leap from what has gone before. Avant-garde materials and advanced manufacturing technology permit these unique shapes, which have tolerances in the micrometer range. In terms of materials, besides the silicon of the blade, nickel comprises the two levers. In terms of technology, LIGA (an acronym derived from the German words for lithography, electroplating, and molding), a process first used for medical applications in the 1980s, creates flawless components, and innovative shapes become possible. Using photo-lithography and electroforming, Girard-Perregaux is able to make very accurate shapes with exceptional surface quality. The result looks like nothing you have ever seen inside a watch and makes for a watch unlike any other.

Imagine the 1966 Perpetual Calendar with the Constant Escapment. It will have stellar accuracy for its perpetual calendar and utilize a groundbreaking technology. Gerard Perregaux claims that the escapement has been tested to 7.2 hz (or 25,920 vph), and they believe that the design’s inherent accuracy makes a high frequency optional, if not superfluous. For this first watch, Girard-Perregaux plans on 21,600 vph. When I travel to Basel for the fair, I will certainly provide an update on the identity of this mystery watch.

This article is written by Max E. Reddick, contributing writer for Monochrome Watches.

14 responses

The challenge will be to design a watch that jides as little as possible from this mechanical marvel and will remain gp style…

Looking forward to it.

It will be interesting to see what Baselworld will show.

Félicitation pour cet article qui est le plus complet et le plus précis (hormis mon nom et prénom mal orthographiés) que j’aie lu depuis… bientôt 5 ans, déjà !

Ce projet correspond à quelques 10 ans de ma vie, soit de 1998 (au sein de la Manufacture des Montres Rolex Bienne) jusqu’à 2008 ou l’échappement en question fût présenté durant le SIHH. Comme il est dit en fin d’article, ce mécanisme a été intégré dans une magnifique pièce que vous aurez tout loisir de découvrir durant BASELWORLD 2013. Même si je ne suis plus directement impliqué dans cette construction, je suis fier d’avoir été l’initiateur de ce projet novateur ; ce fût pour moi l’une des plus belle expérience de ma vie professionnelle.

J’espère sincèrement que le nouveau mouvement qui sera dévoilé d’ici peu fasse la “une” de l’horlogerie et que Girard-Perregaux retrouve son éclat d’antan.

Nicolas Déhon (inventeur de l’échappement Constant)

Thank you so much for your kind words, Nicolas! I’ve corrected your name, sorry for the mistake. Tomorrow I’m visiting Girard-Perregaux in Switzerland to see your constant escapement. I’m very much looking forward to seeing it myself.

Thank you and all the best,

Frank

Nicolas,

It was fascinating to research and write the article. If I Americanized your name, please forgive me and note Frank’s correction. I hope the enthusiasm and detail of the article did justice to your creation.

And did I lie?

🙂

Nice seeing you today Frank!

MLM

Nice to see/meet you again, Mike! And the new timepiece with Constant Escapement could become a game-changer in the next years. Very impressive!

Nice article and a very interesting watch. I wrote the first technical article regarding the GP project a number of years ago for Watch Around magazine after acquiring one of the few Rolex ELF project movements and tech-book. I was hooked!

Although the impulse springs release the same amount of energy upon each cycle, it doesn’t come for free. We invariably think of friction as the energy expended when two or more components interact at somewhat singular points of contact. However there are internal frictions within the components, especially springs. Molecular friction we coud say. GP not only took this into consideration by experimenting with silica components that were not readily available at the time Rolex held their trials, but GP also realized that more power was needed, hence two barrels/mainsprings.

In my personal opinion this concept, and choice of modern materials will take further time to develop it is a worthy subject of horological importance. Bravo to GP for finally getting this concept to the public.

Regards, Ron

Hi Ron:

Great insight and glad to know of your connection with the Constant Escapement. Be glad to know what you think of the final product: the CE in a watch!

Max.

There is a link imbedded in your article regarding the Rolex (ELF) project. The linked page comes up blank. Would you like some photos of the ELF movement to fill the void?

Ron

Bonsoir à tous,

Vous êtes décidément très bien renseigné sur ce forum. Le projet mené chez Rolex par moi-même s’appelait effectivement “Projet ELF”. Rien à voir avec l’industrie pétrochimique cependant. ELF était l’abréviation suivante:

E = Echappement (Escapement)

L = Lame (Thin Spring like a spade)

F = Flambée (Buckled).

Les prototypes que j’avais conçu avait été réalisé avec une technologie horlogère standard. La lame avait été fabriquée par laminage d’un fil rong tel que sont réalisé les spiraux chez Rolex. La seul différence avec un spiral est que l’on cherchait ensuite à obtenir la lame la plus droite possible (ce qui n’était pas simple du tout).

Concernant les “petits noms”, quand j’ai relancé le projet au sein de Girard-Perregaux, sont petit nom était “Échappement Anguinea” j’avais moi-même trouvé ce nom et pensait que sa consonance italienne plairait à feu Luigi Macaluso. Pourquoi Anguinea? C’est la forme d’une courbe mathématique ressemblant étrangement à celle prise par la lame lorsque elle subit un flambage de premier ordre (voir le site mathcurve.com). Quelque semaine avant la le SIHH 2008, M. Macaluso décida de nommer l’échappement Contant à la mémoire de Constant Girard, l’un des fondateur de la marque.

Plus tard, en 2011, un mathématicien féru d’horlogerie que j’avais rencontré à BaselWorld me dit que s’il en avait été l’inventeur, il aurait baptisé le mécanisme ainsi : “Échappement quantique”. Il trouvait que ce nom, emprunté à la physique des quanta, rendait bien compte du paquet d’énergie parfaitement constant que cet échappement distribuait à chaque alternance de l’oscillateur.

Voilà pour la petite histoire (veuillez m’excuser de ne pas m’exprimer en anglais, je manque de précision dans cette langue).

Pour aborder un autre sujet, j’avoue avoir trouvé choquante le communiqué de presse paru à Zurich, en guise de pré-BaselWorld. Prétendre que les travaux portant sur le “Constant Escapement” aient débuté en 2008 n’est pas juste un mensonge par omission ; c’est un mensonge tout court. Visiblement l’on cherche à rompre tout lien qui pourrait permettre de remonter à la source de ce projet ; à la phase ou tout le pré dimensionnement fût calculé. Ce forum est l’un des seuls ou la vérité sur ce projet semble transparaître sans équivoque : MERCI.

Pour finir ma contribution de ce soir, j’aimerais parler de frottement concernant cet échappement. De ce point de vue, je tiens à dire que toutes les interactions entre la bascule d’armage et le ressort d’échappement puis entre la bascule de détente et le petit plateau (Balancier) sont optimales ; les pièce se mènent l’une l’autre en l’absence quasi complète de frottement. Le point faible reste l’interaction entre les roues d’armage et la bascule d’armage. Là, le frottement est considérable et les conditions tribologiques deviennent cruciales.

Je pense donc bien que si une amélioration notable devait apparaître ses prochaines années, c’est bien à ce niveau là que ça se jouera.

Mais, après tout, on en est qu’au début d’une histoire que je souhaite très longue. Thomas Mudge n’a pas inventé un échappement à ancre aussi évolué que ne l’est le Pulsomax ; il a fallu du temps pour que cette version très aboutie de l’échappement à ancre voie le jour (et l’avènement de nouvelles technologies).

An interesting solution to a well known problem. Would this so called buckling, fall in the category of compliant mechanism, as it is all one piece?